A new material for manufacturing insulation for footwear by reusing tyres

STAT-ON, a new device to monitor motor symptoms of Parkinson’s disease

June 21, 2019

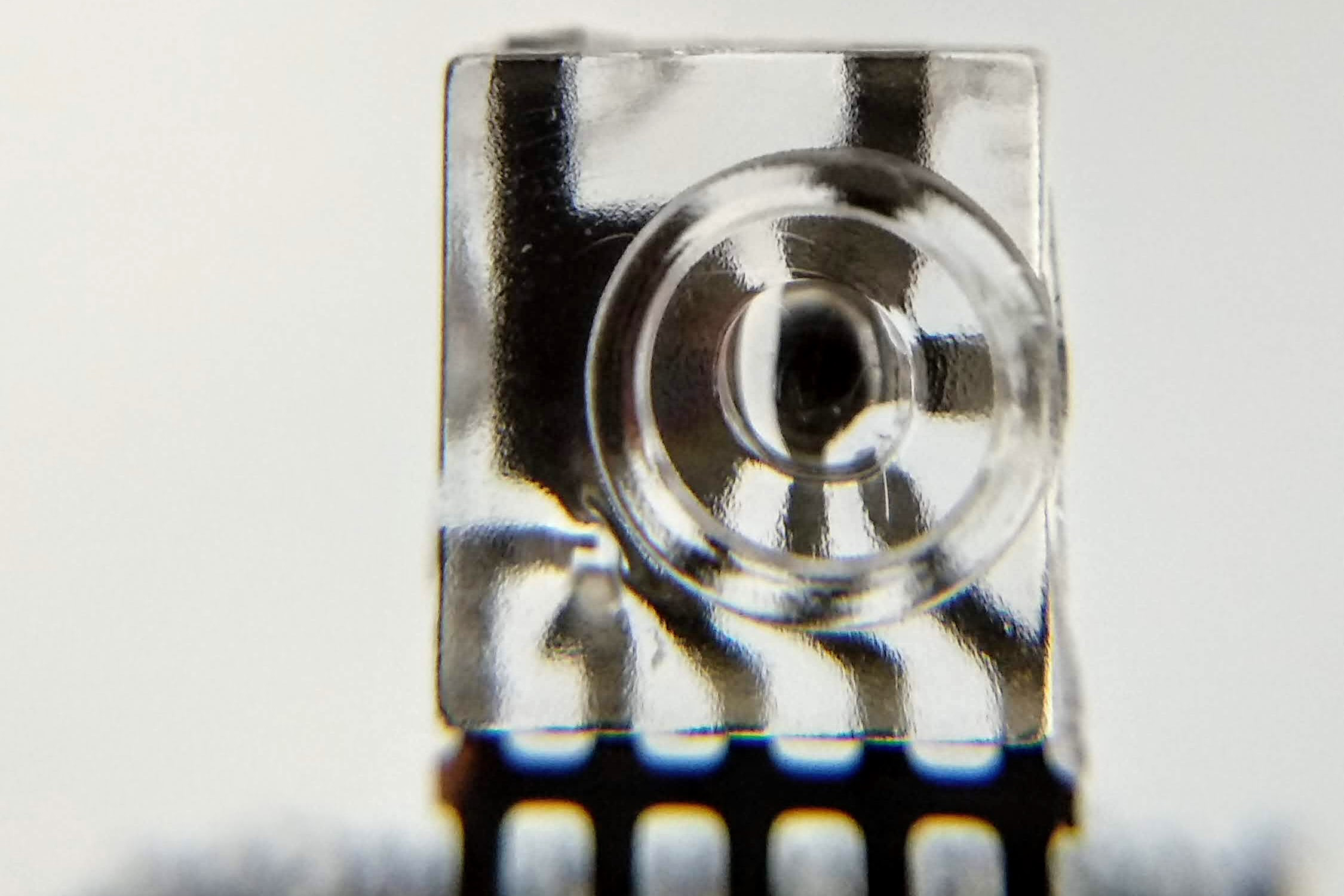

A new manufacturing system for integrated optical components

May 26, 2019It is estimated that around 300,000 tonnes of tyres are discarded in Spain and 2,000,000 tonnes in Europe every year, a third of which end up in illegal dumps. This waste material is difficult to treat and can take around 1,000 years to disappear naturally. The enormous volume of disused tyres has led to new formulas being sought in recent years to give this waste a new lease of life. Products to make road surfaces, material for public works or flooring for children’s playgrounds are some of the ways that have been found to reduce the number of tyres in dumps. However, most end up in energy recovery plants where the waste is burnt, and the resulting energy is used to produce steam and electricity.

A research team from the Universidad Politécnica de Cataluña · BarcelonaTech (UPC), along with researchers from the Universidad Rovira i Virgili (URV), has found a new application for vulcanised rubber from tyres. Through a simple process in which the rubber is combined with a polymer, it can be converted into insulating material for footwear.

The research team, led at the UPC by Ramon Mujal Rosas, from the Department of Electrical Engineering, and at the URV by Marc Marín Genescà, from the Department of Mechanical Engineering, has developed this material after combining vulcanised rubber from types with low proportions of polymers. During the research, which has been published in the journal Applied Sciences, the researchers tested various polymers at a range of concentrations until they found the ideal combination to develop an insulating material for footwear that meets the required criteria of conductivity, elasticity and resistance to fracture for this purpose.

"We have been able to create this new product by adding 10% of polymers to the vulcanised rubber. The best results are found when the polymer used is ethylene/vinyl acetate, which is used to make Eva rubber", said Marc Marín.

In addition to Ramon Mujal Rosas, a member of the UPC who is involved in the project is the researcher Xavier Salueña Berna, from the Department of Mechanical Engineering. Both are lecturers at the Terrassa School of Industrial, Aerospace and Audiovisual Engineering (ESEIAAT).

In addition to the researcher Marco Marín Genescà, who teaches at the School of Chemical Engineering (ETSEQ), other members of the URV team are Jordi Garcia Amorós and Lluís Massaguer Vidal, researchers from the Department of Electrical Engineering and lecturers in the URV Higher Technical School of Engineering (ETSI).

A sustainable solution

In their work, the researchers have also considered the sustainability and economic viability of the product. They believe that using it will lead to savings in companies’ production processes, cutting costs because it will reduce the percentage of raw material that is required, which will be replaced by vulcanised rubber from dumps.

According to the research results, and using data on the volume of footwear production worldwide, Marín stated that "if footwear manufacturers in the world replace the current material with tyre waste that has been ground up – a process that is already carried out in energy recovery plants – and 10% of EVA rubber is added, savings of around 20 million euros could be obtained annually in the cost of raw materials and CO2 emissions could be cut by around 40,000 tonnes".

Currently, UPC and URV researchers are working to find new applications for the same technique. They have obtained promising results with applications such as coatings and trays for cables.

Related Projects

- The Paper Engineering research group (CELBIOTECH) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is participating in a project to develop biodegradable materials from cellulose, to transform them into advanced, eco-friendly bioproducts.

- The Radio Frequency Identification and Flexible Electronics (RFLEX) group at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is participating in ETEXHEALTH. The project is focused on finding solutions based on the application of electronic textile sensors (e-textile) to monitor biometric variables of the human body and the evolution of diseases in a minimally invasive way.

- The technology of the CP4C project, based on hydrogels treated with plasma gas, is being developed by the team of researchers at the PlasmaMedLab and the Biomaterials, Biomechanics and Tissue Engineering Group (BBT) of CREB at the UPC. CP4C is one of the University projects that has obtained a grant from Barcelona Deep Tech Node to accelerate its launch on the market.

- The research group IMEM-BRT of the UPC leads the TherGel project, which aim is to combine the properties of both materials in a conductive polymer hydrogel that could be used in water evaporation systems, as filtration membranes and as solid-state electrolytes that are active in electrochemical cells of capacitive deionisation of salt water.